Starting from channels and gradually ensuring the quality of products and services

Qualification Certification

Supplier Classification System Management

Quality Inspection Process

Storage/Packaging/Transportation Standard Control

Standard Operating Procedures And Database Management

RMA Return Process

Quality Process Overview

Every C-SEA Worldwide order goes through a comprehensive quality control process in one of our five quality hubs. As a result, C-SEA ensures the highest quality testing services and complete transparency, with a detailed quality inspection report delivered with every order.

BOX

DELIVERED

RECEIVER ONE

RECEIVER ONE

REVIEWS &

PHOTOGRAPHS

- Packaging

- Part Number

- Serial Number

- Quantity

- COO

- Lot Codes

- Date Codes

RECEIVER TWO

RECEIVER TWO

REVIEWS &

SCANS

BARCODES

- Packaging

- Part Number

- Serial Number

- Quantity

- COO

- Lot Codes

- Date Codes

QUALITY INSPECTION

QUALITY INSPECTION

INSPECTS

- Markings

- Leads

- Part Top, Bottom, Side

- Acetone

- Marking Permanency

- Scrape

- Dimensions

- Data Sheet

- Magnification

- History/OS

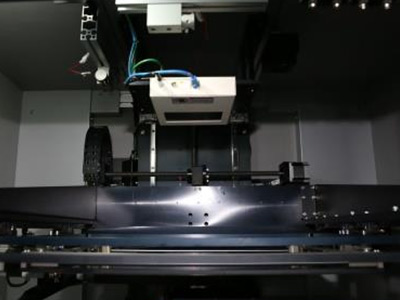

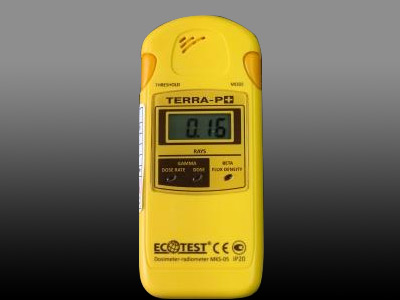

LAB TESTING

LAB TESTING

TESTS USING

- Keyence Scope 2000x

- X-ray

- XRF

- Heated Chemical Test

- Chemical Decap

- Solderability

GENERAL TESTING

GENERAL TESTING

ADDITIONAL

TESTS

- Electrical

- CPU

- Memory

- Storage

- Graphics

- Peripherals